Multi-layer co-extrusion vacuum bag for food packaging

Product Features of Food Packaging Multi-layer Co-extrusion Vacuum Bag (1) high barrier air tightness performance: multi-layer co-extruded film can be a variety of different functions of plastic co-extruded composite into a film, to achieve oxygen, water, carbon dioxide, odor and other high barrier effect. (2) Environmental protection: Because no binder is added, there is no residual agent to pollute the product, which is a green ring packaging material. (3) Strong mechanical properties, high anti-blasting performance, anti-puncture and anti-tear performance, due to the application of multi-layer co-extrusion blow molding technology, there is no layered peeling phenomenon.

Multi-layer co-extruded stretch film can effectively isolate the external environment damage to the product, protect the original quality of the product, the use of multi-layer co-extrusion technology to ensure that the product manufacturing process is more efficient. This technology can produce films with different functions and characteristics according to different needs.

Classification:

Key words:

Multi-layer co-extrusion vacuum bag for food packaging

E-mail:

- Product Description

-

- Commodity name: Multi-layer co-extrusion vacuum bag for food packaging

- Commodity ID: 1230195297657442304

Product Features of Food Packaging Multi-layer Co-extrusion Vacuum Bag (1) high barrier air tightness performance: multi-layer co-extruded film can be a variety of different functions of plastic co-extruded composite into a film, to achieve oxygen, water, carbon dioxide, odor and other high barrier effect. (2) Environmental protection: Because no binder is added, there is no residual agent to pollute the product, which is a green ring packaging material. (3) Strong mechanical properties, high anti-blasting performance, anti-puncture and anti-tear performance, due to the application of multi-layer co-extrusion blow molding technology, there is no layered peeling phenomenon.

Food packaging multi-layer co-extrusion vacuum bag product series

(1) Universal vacuum white bag series

Product performance: the product has high barrier air tightness, good heat sealing, environmental protection, long shelf life, widely used in inner products, aquatic products, frozen food, rice, food and other inner bag packaging.

(2) Ultra high temperature sterilization (UHT) high barrier vacuum series

Product performance: The product structure is LLDPE/TI/EVOH/TI/LLDPE, which meets environmental protection requirements, strong film structure, good heat sealing, high-quality printing effect, and shelf life of 90-150 days. Widely used in Baili bag, Jiale bag, pillow bag, vertical bag, crane mouth bag.

(3) Chemical and pesticide packaging series

Product performance: The product is used for petrochemical raw materials, pesticides, spices, cosmetics, and other packaging. Through the excellent barrier properties of EVOH and nylon, it can effectively prevent the volatilization of the contents, and at the same time, it can also block the erosion of the external odor and moisture on the contents, and ultimately ensure the quality of the product and extend the shelf life.

Product Features of Food Packaging Multi-layer Co-extrusion Vacuum Bag

(1) high barrier air tightness performance: multi-layer co-extruded film can be a variety of different functions of plastic co-extruded composite into a film, to achieve oxygen, water, carbon dioxide, odor and other high barrier effect.

(2) Environmental protection: Because no binder is added, there is no residual agent to pollute the product, which is a green ring packaging material.

(3) Strong mechanical properties, high anti-blasting performance, anti-puncture and anti-tear performance, due to the application of multi-layer co-extrusion blow molding technology, there is no layered peeling phenomenon.

(3) strong performance: oil resistance, moisture resistance, high temperature cooking resistance, low temperature freezing, shelf life, preservation, odor.

(4) Low cost: Compared with glass packaging and aluminum foil packaging, to achieve the same barrier effect, multi-layer co-extruded film has a greater cost advantage.

(5) good heat sealing performance, flexibility, high transparency.

Food packaging multi-layer co-extrusion vacuum bag products for industry

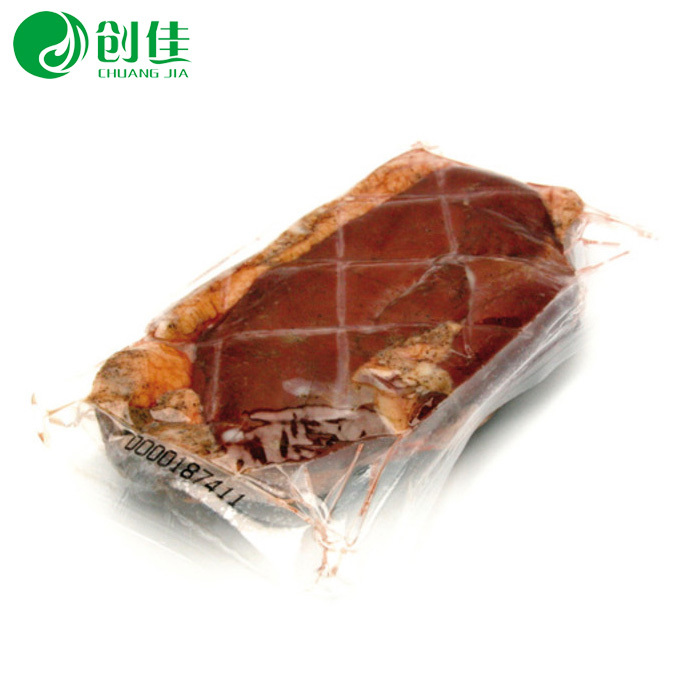

(1) Multi-layer co-extruded vacuum packaging can withstand 121-135 ℃ cooking sterilization, the time is 40 minutes. It is widely used in the packaging of steamed food, raw and cooked meat products, seafood, dairy products, dried fish, aquatic products, oily food, cured meat, roast duck, roast chicken, roast pig, quick-frozen food, ham, pickled meat products, sausage, cooked meat products, pickles, bean products, seasonings and other products, which can maintain the original flavor of the original color, effectively prevent oil oxidation, prevent oil penetration, and effectively keep the packaging clean, and used for aseptic packaging, odor loading, etc.

(2) pesticides, chemical products, anti-oxidation, anti-penetration, anti-moisture packaging, widely used in cyclohexane, petroleum ether, ethyl acetate, pentane, benzene and ketone packaging.

(3) The pollution and mildew of grain and its products are widely used in the packaging of rice, peanuts, sesame, beans, walnuts, feed, tobacco and other large stacks, storage and circulation links to prevent insect columns, deterioration, and extend shelf life.

(4) Moisture-proof, oxidation-proof and deterioration-proof of precious medicinal materials.

(5) coffee, cocoa, spices, oils, cosmetics raw materials to protect the aroma, quality, taste, color. (6) Packaging of drug products.

(7) Packaging of industrial products: anti-oxidation and anti-corrosion packaging of electronic products, precision machinery accessories, welding materials, circuit boards, optical accessories, aircraft accessories, etc.

Key words:- 食品包装多层共挤真空袋

1. Multi-layer co-extruded stretch film has excellent tensile strength, can withstand the pressure of various complex environments, and ensure the durability and reliability of the product.

2. The multi-layer co-extruded stretch film with high transparency can clearly display the goods and improve the consumer's desire to buy. At the same time, high transparency also increases the aesthetics of the product.

3. Multi-layer co-extruded stretch film is made of environmentally friendly and non-toxic materials, which meets food safety standards and ensures the health and safety of consumers. In addition, it can also be recycled to reduce environmental pollution. This material can be used in food packaging, medical packaging and other fields. It has good sealing performance, can prevent the intrusion of moisture and moisture, and ensure the quality and shelf life of the product. At the same time, it also has excellent waterproof and moisture-proof performance, which can protect the product from damage in various environments. In addition, the multi-layer co-extruded stretched film also has precise thickness control performance, and the thickness of the film can be adjusted according to different needs to meet different use requirements. Finally, the multi-layer co-extruded stretch film has a wide range of applications and can be used in product packaging and transportation in the fields of food, medical, and industry. It has strong adaptability and can meet the needs and requirements of different fields.

The application of coextrusion film in fresh meat has obvious advantages. First of all, its high barrier properties effectively isolate oxygen, prevent fresh meat oxidation deterioration, extend the shelf life. Secondly, the good water permeability and air permeability of the co-extruded film helps to maintain the natural flavor of meat. Furthermore, its strong material can resist mechanical damage during transportation and protect the integrity of fresh meat. In addition, the co-extruded film is environmentally friendly and non-toxic, and meets food safety standards. Compared to traditional packaging materials, coextruded films are more cost effective and easy to handle. In summary, the co-extrusion film shows significant advantages in fresh meat preservation, transportation and cost control, and is an ideal choice for fresh meat packaging.

Message

Message

Contact Us

Address: No.18, Longjin Avenue, Qianku Town, Cangnan County, Wenzhou City, Zhejiang Province

Mobile: 86-18072086666(Mr. Wang)

Telephone: 86-577-68526265

E-mail:manager@wzcjbz.cn