Vacuum Food Packaging Bag

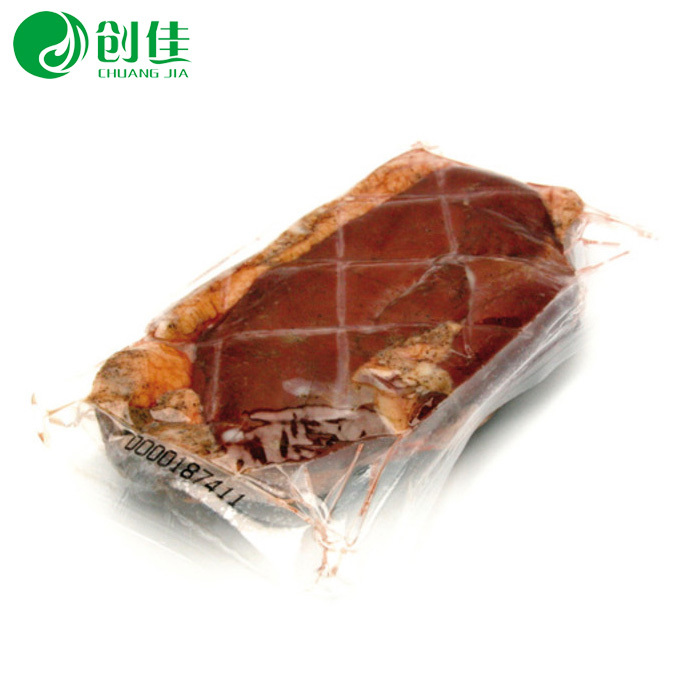

Vacuum food packaging bag: put the food into the packaging bag, extract the air in the packaging bag, and complete the sealing process after reaching the predetermined vacuum degree. Vacuum food packaging bags put food into the packaging bag, extract the air in the packaging bag to reach a predetermined vacuum, and then fill in nitrogen, carbon dioxide, oxygen and other gases, and then complete the sealing process.

Multi-layer co-extruded stretch film can effectively isolate the external environment damage to the product, protect the original quality of the product, the use of multi-layer co-extrusion technology to ensure that the product manufacturing process is more efficient. This technology can produce films with different functions and characteristics according to different needs.

Classification:

Key words:

Vacuum Food Packaging Bag

E-mail:

- Product Description

-

- Commodity name: Vacuum Food Packaging Bag

- 计费重量: 0

Vacuum food packaging bag: put the food into the packaging bag, extract the air in the packaging bag, and complete the sealing process after reaching the predetermined vacuum degree. Vacuum food packaging bags put food into the packaging bag, extract the air in the packaging bag to reach a predetermined vacuum, and then fill in nitrogen, carbon dioxide, oxygen and other gases, and then complete the sealing process.

Vacuum food packaging bag: put the food into the packaging bag, extract the air in the packaging bag, and complete the sealing process after reaching the predetermined vacuum degree. Vacuum food packaging bags put food into the packaging bag, extract the air in the packaging bag to reach a predetermined vacuum, and then fill in nitrogen, carbon dioxide, oxygen and other gases, and then complete the sealing process.

The main function of vacuum food packaging bag is deoxygenation, in order to help prevent food deterioration, its principle is relatively simple, because food mold deterioration is mainly caused by the activities of microorganisms, and most microorganisms (such as mold and yeast) need oxygen to survive, and vacuum packaging is the use of this principle, the packaging bag and food cells within the oxygen pumping out, so that microorganisms lose the "living environment". Experiments show that when the oxygen concentration in the packaging bag is less than 1%, the growth and reproduction rate of microorganisms will drop sharply, and when the oxygen concentration is less than or equal to 5%, most microorganisms will be inhibited and stop reproduction.

(Note: Vacuum food packaging bags can not inhibit the reproduction of anaerobic bacteria and enzyme reaction caused by food deterioration and discoloration, so it needs to be combined with other auxiliary methods, such as refrigeration, quick freezing, dehydration, high temperature sterilization, irradiation sterilization, microwave sterilization, salt cell system, etc.)

Vacuum food packaging bag scope of application

1. Vacuum packaging

① Pickled products: sausage, ham, bacon, salted duck, etc.; ② Pickled vegetables: pickled mustard tuber, dried turnip, turnip, kimchi, etc.; ③ Bean products: dried bean curd, vegetarian chicken, bean paste, etc.; ④ Cooked food: roast chicken, roast duck, pickled beef, etc.; ⑤ Convenience food: rice, instant wet noodles, cooked vegetables, etc.; ⑥ Soft canned food: clear water, etc;

2. Vacuum inflatable packaging

① Tea, nuts, melon seeds, meat floss, etc.; ② fried potato chips, puffed food, fruit and vegetable chips, etc.; ③ cakes, moon cakes, etc.; ④ milk powder, coffee, chocolate, etc.; ⑤ all kinds of local specialties, valuable Chinese herbal medicines; ⑥ all kinds of dehydrated vegetables.

Key words:- 真空食品包装袋

1. Multi-layer co-extruded stretch film has excellent tensile strength, can withstand the pressure of various complex environments, and ensure the durability and reliability of the product.

2. The multi-layer co-extruded stretch film with high transparency can clearly display the goods and improve the consumer's desire to buy. At the same time, high transparency also increases the aesthetics of the product.

3. Multi-layer co-extruded stretch film is made of environmentally friendly and non-toxic materials, which meets food safety standards and ensures the health and safety of consumers. In addition, it can also be recycled to reduce environmental pollution. This material can be used in food packaging, medical packaging and other fields. It has good sealing performance, can prevent the intrusion of moisture and moisture, and ensure the quality and shelf life of the product. At the same time, it also has excellent waterproof and moisture-proof performance, which can protect the product from damage in various environments. In addition, the multi-layer co-extruded stretched film also has precise thickness control performance, and the thickness of the film can be adjusted according to different needs to meet different use requirements. Finally, the multi-layer co-extruded stretch film has a wide range of applications and can be used in product packaging and transportation in the fields of food, medical, and industry. It has strong adaptability and can meet the needs and requirements of different fields.

The application of coextrusion film in fresh meat has obvious advantages. First of all, its high barrier properties effectively isolate oxygen, prevent fresh meat oxidation deterioration, extend the shelf life. Secondly, the good water permeability and air permeability of the co-extruded film helps to maintain the natural flavor of meat. Furthermore, its strong material can resist mechanical damage during transportation and protect the integrity of fresh meat. In addition, the co-extruded film is environmentally friendly and non-toxic, and meets food safety standards. Compared to traditional packaging materials, coextruded films are more cost effective and easy to handle. In summary, the co-extrusion film shows significant advantages in fresh meat preservation, transportation and cost control, and is an ideal choice for fresh meat packaging.

Message

Message

Contact Us

Address: No.18, Longjin Avenue, Qianku Town, Cangnan County, Wenzhou City, Zhejiang Province

Mobile: 86-18072086666(Mr. Wang)

Telephone: 86-577-68526265

E-mail:manager@wzcjbz.cn