Eleven-layer cast film

Industrial use and characteristics of eleven layer cast film: 1. Electronic packaging The eleven-layer cast film can meet the needs of anti-static, dustproof, moisture-proof and moisture-resistant high-end electronic components, especially for electronic components with a long shipping period, and high-barrier packaging can effectively stabilize their quality. 2. Auto parts lining film

Multi-layer co-extruded stretch film can effectively isolate the external environment damage to the product, protect the original quality of the product, the use of multi-layer co-extrusion technology to ensure that the product manufacturing process is more efficient. This technology can produce films with different functions and characteristics according to different needs.

Classification:

Key words:

Eleven-layer cast film

E-mail:

- Product Description

-

- Commodity name: Eleven-layer cast film

- Commodity ID: 1230195296264933376

Industrial use and characteristics of eleven layer cast film: 1. Electronic packaging The eleven-layer cast film can meet the needs of anti-static, dustproof, moisture-proof and moisture-resistant high-end electronic components, especially for electronic components with a long shipping period, and high-barrier packaging can effectively stabilize their quality. 2. Auto parts lining film

Industrial use and characteristics of eleven layer cast film:

1. Electronic packaging

The eleven-layer cast film can meet the needs of anti-static, dustproof, moisture-proof and moisture-resistant high-end electronic components, especially for electronic components with a long shipping period, and high-barrier packaging can effectively stabilize their quality.

2. Auto parts lining film

Applied to automobile carpet film and wheel film. The eleven-layer cast film is very suitable for processing and making automobile forming carpet. The main molding carpet for automobiles includes a three-layer structure, which is more environmentally friendly and soundproof, and can better adapt to the lightweight requirements of automobiles.

3. Packaging of industrial components

The eleven-layer cast film can meet the requirements of rust prevention, moisture resistance, moisture resistance, puncture resistance, and easy stretch molding required by high-end industrial originals.

4. Chemical packaging

High barrier eleven layer cast film made of emulsifiable concentrate pesticide chemical packaging bags, compared with glass bottles, plastic bottles packaging more space-saving, more secure, in line with the development trend of pesticide packaging industry, is widely used in pesticides, emulsifiable concentrate and other chemical products packaging.

5. Daily chemical packaging

At present, eleven-layer cast film is widely used in daily chemical packaging, especially for facial mask packaging, mainly using co-extruded film (substrate film) and aluminum foil and PET, BOPP, NY composite, or with PET aluminized film, OPP aluminized film and co-extruded film. Aluminum-plastic composite flexible packaging has the characteristics of beautiful fragrance, moisture-proof, high barrier, light-proof, UV-proof, long storage period, etc., and is used in medicine and cosmetics.

In addition, the eleven-layer cast film can also be used for packaging of books and periodicals, calligraphy and painting, etc., which can meet the needs of bills, books and periodicals, calligraphy and painting and other products with moisture resistance and humidity resistance. Not only that, it can also meet the puncture resistance and high permeability film effect required by high-end cushioning packaging.

The eleven-layer cast film can be freely combined with formula, the thickness of each layer of various structures can be adjusted within a certain range according to customer requirements, and the raw materials of each layer can also be adjusted according to customer packaging requirements to meet the functional requirements of customer products such as high barrier, high transparency, puncture resistance, easy stretching, easy forming, cooking resistance, freezing resistance, low temperature storage, easy uncovering, easy tearing, anti-fog, anti-static and other functional requirements.

Key words:- 十一层流延膜

1. Multi-layer co-extruded stretch film has excellent tensile strength, can withstand the pressure of various complex environments, and ensure the durability and reliability of the product.

2. The multi-layer co-extruded stretch film with high transparency can clearly display the goods and improve the consumer's desire to buy. At the same time, high transparency also increases the aesthetics of the product.

3. Multi-layer co-extruded stretch film is made of environmentally friendly and non-toxic materials, which meets food safety standards and ensures the health and safety of consumers. In addition, it can also be recycled to reduce environmental pollution. This material can be used in food packaging, medical packaging and other fields. It has good sealing performance, can prevent the intrusion of moisture and moisture, and ensure the quality and shelf life of the product. At the same time, it also has excellent waterproof and moisture-proof performance, which can protect the product from damage in various environments. In addition, the multi-layer co-extruded stretched film also has precise thickness control performance, and the thickness of the film can be adjusted according to different needs to meet different use requirements. Finally, the multi-layer co-extruded stretch film has a wide range of applications and can be used in product packaging and transportation in the fields of food, medical, and industry. It has strong adaptability and can meet the needs and requirements of different fields.

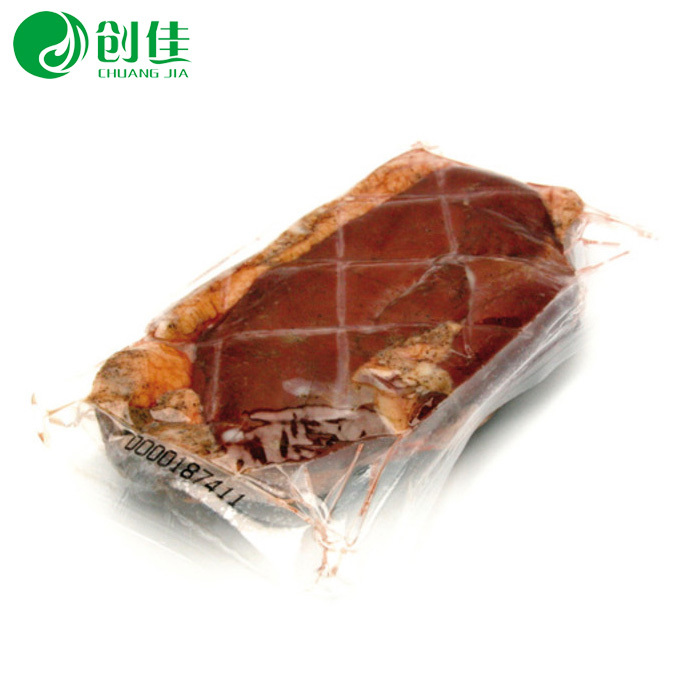

The application of coextrusion film in fresh meat has obvious advantages. First of all, its high barrier properties effectively isolate oxygen, prevent fresh meat oxidation deterioration, extend the shelf life. Secondly, the good water permeability and air permeability of the co-extruded film helps to maintain the natural flavor of meat. Furthermore, its strong material can resist mechanical damage during transportation and protect the integrity of fresh meat. In addition, the co-extruded film is environmentally friendly and non-toxic, and meets food safety standards. Compared to traditional packaging materials, coextruded films are more cost effective and easy to handle. In summary, the co-extrusion film shows significant advantages in fresh meat preservation, transportation and cost control, and is an ideal choice for fresh meat packaging.

Message

Message

Contact Us

Address: No.18, Longjin Avenue, Qianku Town, Cangnan County, Wenzhou City, Zhejiang Province

Mobile: 86-18072086666(Mr. Wang)

Telephone: 86-577-68526265

E-mail:manager@wzcjbz.cn