High Barrier Stretch Film | High Barrier Vacuum Stretch Film for Food Packaging

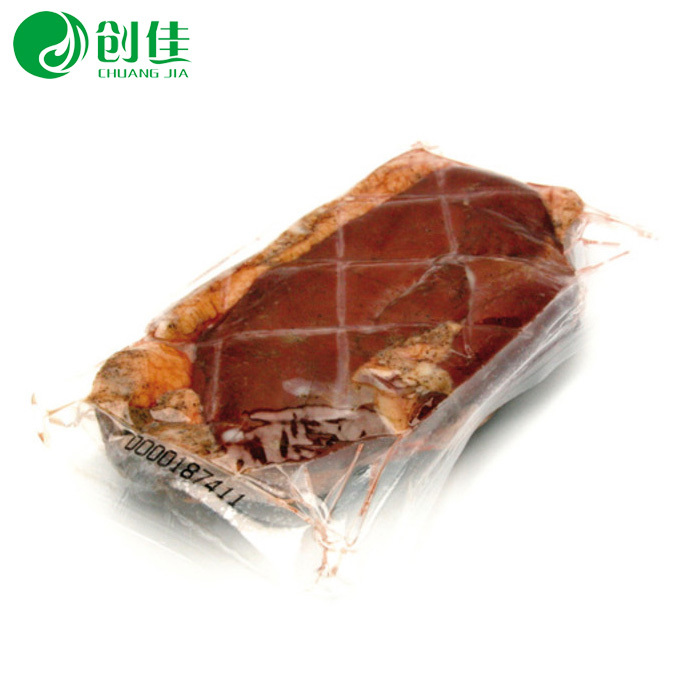

The company introduced multi-layer co-extrusion casting production equipment, specializing in the production of eleven-layer co-extrusion high barrier film. The production specifications are 160*2600mm * 0.05-0.35mm, and there are two kinds of low-temperature freezing and high-temperature cooking vacuum high barrier film. Frozen packaging is suitable for frozen fresh-keeping packaging of pork, beef and mutton, chicken, duck, goose, fish and shrimp and seafood from -18 ℃ to -45 ℃. High temperature can withstand 121 ℃ reverse pressure kettle cooking, suitable for packaging all kinds of cooked meat food (chicken, duck, goose, pig).

Multi-layer co-extruded stretch film can effectively isolate the external environment damage to the product, protect the original quality of the product, the use of multi-layer co-extrusion technology to ensure that the product manufacturing process is more efficient. This technology can produce films with different functions and characteristics according to different needs.

Classification:

Key words:

High Barrier Stretch Film | High Barrier Vacuum Stretch Film for Food Packaging

E-mail:

- Product Description

-

- Commodity name: High Barrier Stretch Film | High Barrier Vacuum Stretch Film for Food Packaging

- Commodity ID: CJ-021

The company introduced multi-layer co-extrusion casting production equipment, specializing in the production of eleven-layer co-extrusion high barrier film. The production specifications are 160*2600mm * 0.05-0.35mm, and there are two kinds of low-temperature freezing and high-temperature cooking vacuum high barrier film. Frozen packaging is suitable for frozen fresh-keeping packaging of pork, beef and mutton, chicken, duck, goose, fish and shrimp and seafood from -18 ℃ to -45 ℃. High temperature can withstand 121 ℃ reverse pressure kettle cooking, suitable for packaging all kinds of cooked meat food (chicken, duck, goose, pig).

Product features:

The company introduced multi-layer co-extrusion casting production equipment, specializing in the production of eleven-layer co-extrusion high barrier film. The production specifications are 160*2600mm * 0.05-0.35mm, and there are two kinds of low-temperature freezing and high-temperature cooking vacuum high barrier film. Frozen packaging is suitable for frozen fresh-keeping packaging of pork, beef and mutton, chicken, duck, goose, fish and shrimp and seafood from -18 ℃ to -45 ℃. High temperature can withstand 121 ℃ reverse pressure kettle cooking, suitable for packaging all kinds of cooked meat food (chicken, duck, goose, pig).The film has the characteristics of no pollution, high barrier, strong function, high strength, etc., and has a strong puncture resistance, which can greatly extend the shelf life of your company's products and maintain the original unique flavor of food. The product is of high quality and low price. Compared with dry composite packaging materials, composite materials must be bonded with glue. Aromatic and aliphatic glue contain harmful substances and are easy to freely penetrate into meat products. Co-extruded high-barrier packaging materials do not use adhesives, thus preventing the pollution of food by harmful substances such as esters and benzene, ensuring food safety and no air leakage. The vacuum degree of co-extruded high-barrier packaging can reach 100, and dry composite materials are generally 90%.The company in accordance with the "co-extruded film quality standards", specializing in the production of automatic continuous vacuum packaging machine with stretch film. While providing products, we also provide you with perfect technical services. We sincerely look forward to cooperating with you in various forms to achieve the goal of win-win.The company's products are mainly divided into two categories:

1. High temperature, high barrier stretch film, structure: PA/TIE/PP/TIE/PA/EVOH/PATIE/PP/PP/PP. This series of films are mainly used for packaging products that need high temperature sterilization. For example: meat products containing bone and thorns; hard air-dried meat products and all kinds of salted eggs and bean products that need to be sterilized at high temperature.2. Low temperature, high barrier stretch film, structure: PA/TIE/PE/TIE/PA/EVOH/PA/TIE/PE/PE/PE. This series of films are mainly used for pasteurization of low temperature meat products. Packaging of fish and aquatic products.(structure) eleven-layer co-extrusionMaterials PE, PP, PA, EVOH, TIE, etc[Performance] High temperature can withstand 121 ℃ back pressure kettle cookingProduct suitable for packaging 〕Raw meat: frozen beef, frozen pork, meat pieces, meat slices;Meat products: ham, bacon, sausage, barbecue, roast chicken, marinated eggs;Dairy products: cheese, butter;Aquatic products: frozen fish, pickled fish, simulated crab meat;Powder products: coffee, powdered cheese;Specialty categories: pickles, peanuts, dates, dried and fresh vegetables, local specialties, etc.Membrane for medical infusion bags.

1. Multi-layer co-extruded stretch film has excellent tensile strength, can withstand the pressure of various complex environments, and ensure the durability and reliability of the product.

2. The multi-layer co-extruded stretch film with high transparency can clearly display the goods and improve the consumer's desire to buy. At the same time, high transparency also increases the aesthetics of the product.

3. Multi-layer co-extruded stretch film is made of environmentally friendly and non-toxic materials, which meets food safety standards and ensures the health and safety of consumers. In addition, it can also be recycled to reduce environmental pollution. This material can be used in food packaging, medical packaging and other fields. It has good sealing performance, can prevent the intrusion of moisture and moisture, and ensure the quality and shelf life of the product. At the same time, it also has excellent waterproof and moisture-proof performance, which can protect the product from damage in various environments. In addition, the multi-layer co-extruded stretched film also has precise thickness control performance, and the thickness of the film can be adjusted according to different needs to meet different use requirements. Finally, the multi-layer co-extruded stretch film has a wide range of applications and can be used in product packaging and transportation in the fields of food, medical, and industry. It has strong adaptability and can meet the needs and requirements of different fields.

The application of coextrusion film in fresh meat has obvious advantages. First of all, its high barrier properties effectively isolate oxygen, prevent fresh meat oxidation deterioration, extend the shelf life. Secondly, the good water permeability and air permeability of the co-extruded film helps to maintain the natural flavor of meat. Furthermore, its strong material can resist mechanical damage during transportation and protect the integrity of fresh meat. In addition, the co-extruded film is environmentally friendly and non-toxic, and meets food safety standards. Compared to traditional packaging materials, coextruded films are more cost effective and easy to handle. In summary, the co-extrusion film shows significant advantages in fresh meat preservation, transportation and cost control, and is an ideal choice for fresh meat packaging.

Message

Message

Contact Us

Address: No.18, Longjin Avenue, Qianku Town, Cangnan County, Wenzhou City, Zhejiang Province

Mobile: 86-18072086666(Mr. Wang)

Telephone: 86-577-68526265

E-mail:manager@wzcjbz.cn