Pesticide and EC Packaging Film | Eleven-layer Co-extrusion Cast Film

The film has the characteristics of no pollution, high barrier, strong function, low cost, small capacity ratio, high strength and flexible structure. And has a strong puncture resistance, can greatly extend the shelf life of your company's products, maintain the original unique flavor of food, product quality and low price, compared with dry composite packaging materials, composite materials must be bonded with glue, including aromatic and aliphatic glue containing harmful substances, easy to freely penetrate into meat products, co-extrusion of high barrier packaging materials process characteristics: the resin raw materials with different functions, such as PA/PE/PP/TIE/EVOH, are respectively melted and extruded, merged in a die through their respective flow channels, then blown and molded, and cooled and compounded together.

Multi-layer co-extruded stretch film can effectively isolate the external environment damage to the product, protect the original quality of the product, the use of multi-layer co-extrusion technology to ensure that the product manufacturing process is more efficient. This technology can produce films with different functions and characteristics according to different needs.

Classification:

Key words:

Pesticide and EC Packaging Film | Eleven-layer Co-extrusion Cast Film

E-mail:

- Product Description

-

- Commodity name: Pesticide and EC Packaging Film | Eleven-layer Co-extrusion Cast Film

- Commodity ID: CJ-024

The film has the characteristics of no pollution, high barrier, strong function, low cost, small capacity ratio, high strength and flexible structure. And has a strong puncture resistance, can greatly extend the shelf life of your company's products, maintain the original unique flavor of food, product quality and low price, compared with dry composite packaging materials, composite materials must be bonded with glue, including aromatic and aliphatic glue containing harmful substances, easy to freely penetrate into meat products, co-extrusion of high barrier packaging materials process characteristics: the resin raw materials with different functions, such as PA/PE/PP/TIE/EVOH, are respectively melted and extruded, merged in a die through their respective flow channels, then blown and molded, and cooled and compounded together.

Product features:

The film has the characteristics of no pollution, high barrier, strong function, low cost, small capacity ratio, high strength and flexible structure. And has a strong puncture resistance, can greatly extend the shelf life of your company's products, maintain the original unique flavor of food, product quality and low price, compared with dry composite packaging materials, composite materials must be bonded with glue, including aromatic and aliphatic glue containing harmful substances, easy to freely penetrate into meat products, co-extrusion of high barrier packaging materials process characteristics: the resin raw materials with different functions, such as PA/PE/PP/TIE/EVOH, are respectively melted and extruded, merged in a die through their respective flow channels, then blown and molded, and cooled and compounded together.Co-extrusion film to prevent the ester, benzene and other harmful substances on the food pollution, to ensure food safety does not leak, this kind of film pumping vacuum almost up to 100, and dry composite materials are generally in 90%.The company in accordance with the, specializing in the production of automatic vacuum packaging special stretch film. While providing products, we also provide you with perfect technical services. We sincerely look forward to cooperating with you in various forms to achieve the goal of creating a win-win situation. Several major features of seven/nine layer coextruded film:

1. high barrier properties The barrier properties of different functional plastic materials are very different to achieve high barrier effects on oxygen, water, carbon dioxide, odor, etc.The 2. has strong oil resistance, moisture resistance, high temperature resistance, low temperature resistance, high strength and other excellent characteristics, quality, fresh, taste, long shelf life, can be used for vacuum packaging, aseptic packaging, liquid packaging, inflatable packaging.Low 3. cost Compared with glass packaging, aluminum foil packaging and other plastic packaging, to achieve the same barrier effect, the seven-layer/nine-layer co-extruded film has a greater cost advantage. Due to the simple process, the film products produced can be reduced by 10-20% compared with dry composite films and other composite films.The 4. structure design is flexible and different structural designs, such as layer structure or non-layer structure, can meet your different quality requirements for products.The high 5. strength seven-layer/nine-layer coextruded film has the characteristics of stretching during processing. The strength of the plastic can be improved after stretching. Plastic materials such as nylon, metallocene, polyethylene, etc. are added in the middle to make it have more than The composite strength of general plastic packaging, there is no delamination peeling phenomenon, good flexibility and excellent heat sealing performance.The 6. capacity is smaller than the seven-layer/nine-layer co-extruded film can be vacuum shrink-wrapped, with a capacity-to-volume ratio of nearly 100%, which is incomparable to glass, iron cans and paper packaging.The 7. is pollution-free and does not contain benzene, esters and other harmful substances on food pollution. During the entire life cycle of the product, it does not cause pollution to the human body and the environment, solves the problem of secondary pollution, and fully meets the requirements of environmental protection and health in the world today., Is an ideal packaging material.

1. Multi-layer co-extruded stretch film has excellent tensile strength, can withstand the pressure of various complex environments, and ensure the durability and reliability of the product.

2. The multi-layer co-extruded stretch film with high transparency can clearly display the goods and improve the consumer's desire to buy. At the same time, high transparency also increases the aesthetics of the product.

3. Multi-layer co-extruded stretch film is made of environmentally friendly and non-toxic materials, which meets food safety standards and ensures the health and safety of consumers. In addition, it can also be recycled to reduce environmental pollution. This material can be used in food packaging, medical packaging and other fields. It has good sealing performance, can prevent the intrusion of moisture and moisture, and ensure the quality and shelf life of the product. At the same time, it also has excellent waterproof and moisture-proof performance, which can protect the product from damage in various environments. In addition, the multi-layer co-extruded stretched film also has precise thickness control performance, and the thickness of the film can be adjusted according to different needs to meet different use requirements. Finally, the multi-layer co-extruded stretch film has a wide range of applications and can be used in product packaging and transportation in the fields of food, medical, and industry. It has strong adaptability and can meet the needs and requirements of different fields.

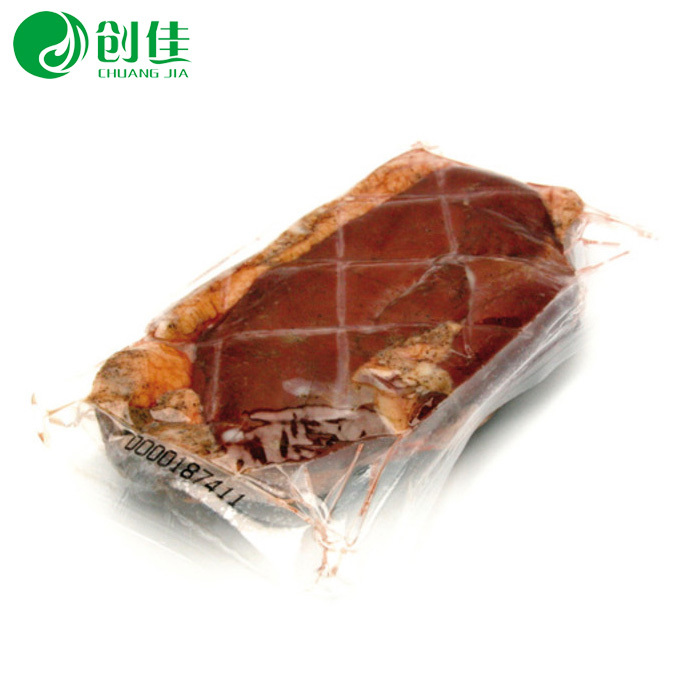

The application of coextrusion film in fresh meat has obvious advantages. First of all, its high barrier properties effectively isolate oxygen, prevent fresh meat oxidation deterioration, extend the shelf life. Secondly, the good water permeability and air permeability of the co-extruded film helps to maintain the natural flavor of meat. Furthermore, its strong material can resist mechanical damage during transportation and protect the integrity of fresh meat. In addition, the co-extruded film is environmentally friendly and non-toxic, and meets food safety standards. Compared to traditional packaging materials, coextruded films are more cost effective and easy to handle. In summary, the co-extrusion film shows significant advantages in fresh meat preservation, transportation and cost control, and is an ideal choice for fresh meat packaging.

Message

Message

Contact Us

Address: No.18, Longjin Avenue, Qianku Town, Cangnan County, Wenzhou City, Zhejiang Province

Mobile: 86-18072086666(Mr. Wang)

Telephone: 86-577-68526265

E-mail:manager@wzcjbz.cn